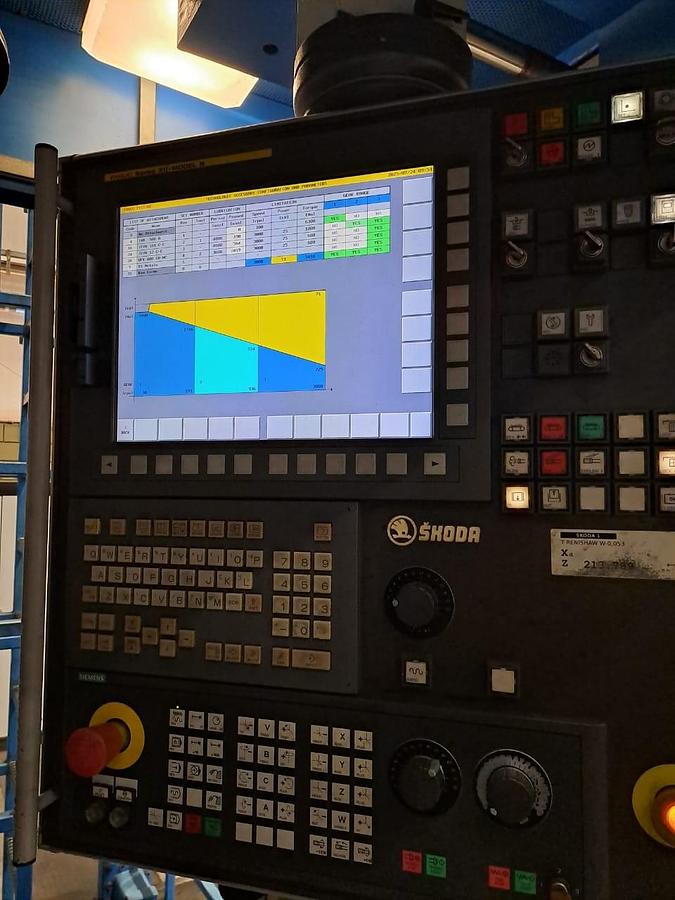

Skoda HCW 1-150 5/14M CNC Heavy-Duty Floor Type Horizontal Boring Machine

Skoda HCW 1-150 5/14M CNC Heavy-Duty Floor Type Horizontal Boring Machine

Description

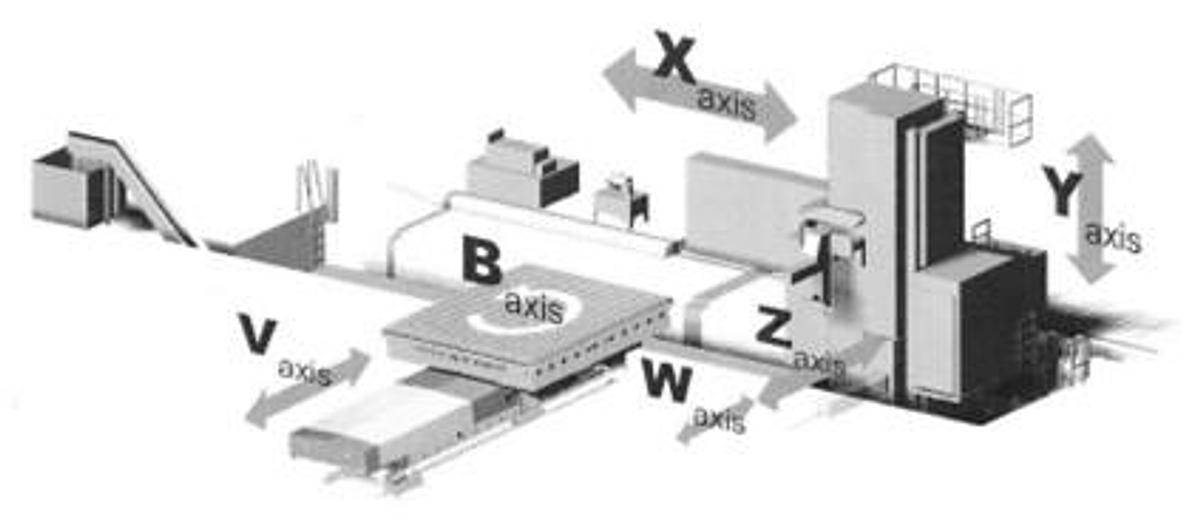

With 4 Axes Operating Simultaneously, For Milling, Drilling and Boring of Heavy-Duty Parts

GE Fanuc Series 31i Model B CC Control System

4 Axis Operating Simultaneously, For Milling, Drilling, And Boring On Heavy Large Parts,

60 Position Automation Tool Changer

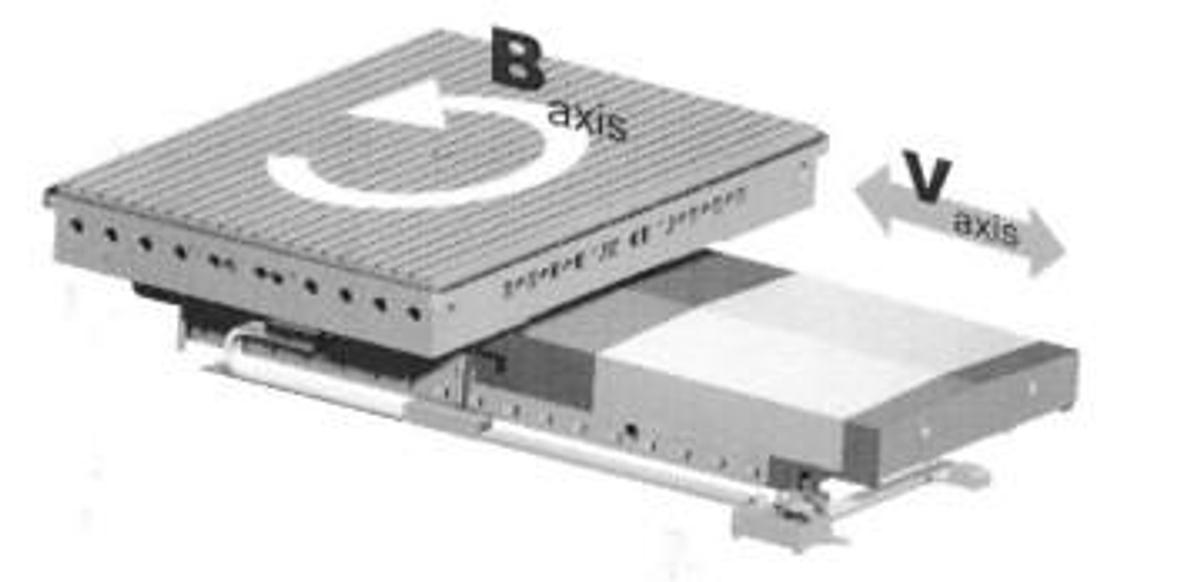

(2) SKODA TDV 70 L D100 Rotary Tables with Longitudinal Travel

Number of Tables - 2

Table Size 4000 x 4000 mm

Table Load Capacity 70 Tons

V-Axis Longitudinal Travel of 2500 mm

B -Axis (rotational) of 360 degrees

B-Axis Increment 0.0001 degrees

2-Axis Continuous Milling Head from 1ST Axis 0 – 360 degrees

2nd Axis +/- 95 degrees

Head pick and place rack (AAC) for 4+1 accessories

IFW 12 C-E Angular Milling Head

IFVW 101 C-E Angular Milling Head

UFK 600 CR-NC Universal Milling Head

IWD 500 A Facing Head

Tool Cooling System.

Tool management

Remote diagnosis

Language expansion

Tool cooling equipment

Automatic tool change

Renishaw RMP 60 radio probe for part measurement

Floor Plates Plate Type D18/40

Chip conveyor

All Hydrostatic Guideways

Entire Machine Structure Made of Cast Iron

Heads:

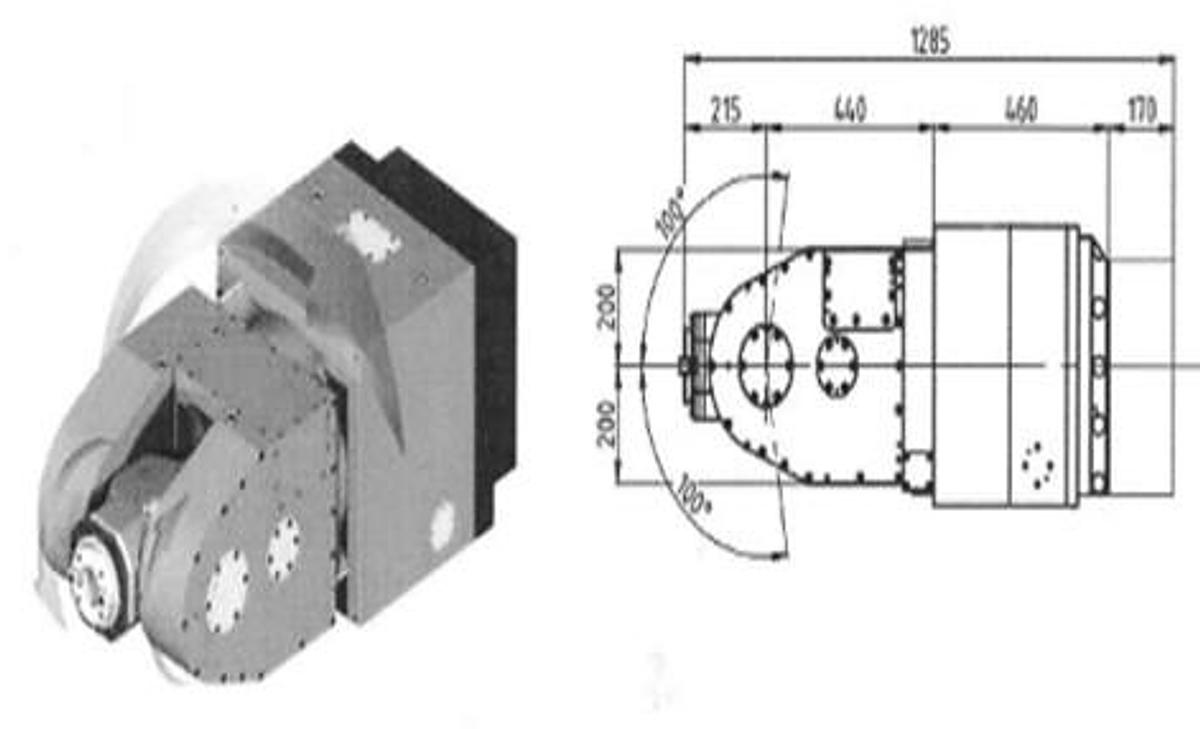

2- Axis Universal Milling Head UFK 600 CR-NC

- Automatic tool clamping.

- Continuous rotation of the headstock on 2 axes.

- External and internal cooling of the tool.

- Automatic loading and clamping on the machine.

- Clamping cavity on the spindle (DIN 69871 – AD) ISO 50

- Max. power (at 400 rpm) 25kW

- Max. torque (up to 400 rpm) 600 Nm

- Max. rotation 3,000 rpm

- Transmission ratio between the machine spindle and headstock spindle 1:1

- Headstock rotation on 1ST axis 1 0-360 degrees

- Headstock rotation on 2nd axis +/- 100 degrees

- Weight 850 kg

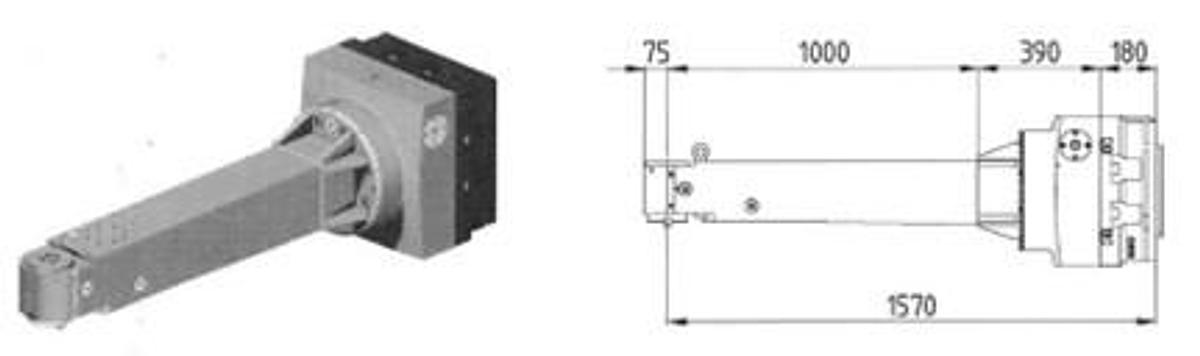

Angular Milling Head IFW 12 C-E

- Manual tool clamping.

- Indexed head rotation of 1°

- External tool cooling.

- Automatic loading and clamping on the machine.

- Clamping cavity on the spindle (DIN 69871 – AD) ISO 50

- Max. power (from 400 rpm) 25kW

- Max. torque (up to 400 rpm) 600 Nm

- Max. rotation 3,000 rpm

- Transmission ratio between machine spindle and headstock spindle 1:1

- Head rotation 0-360 degrees

- Weight 650 kg

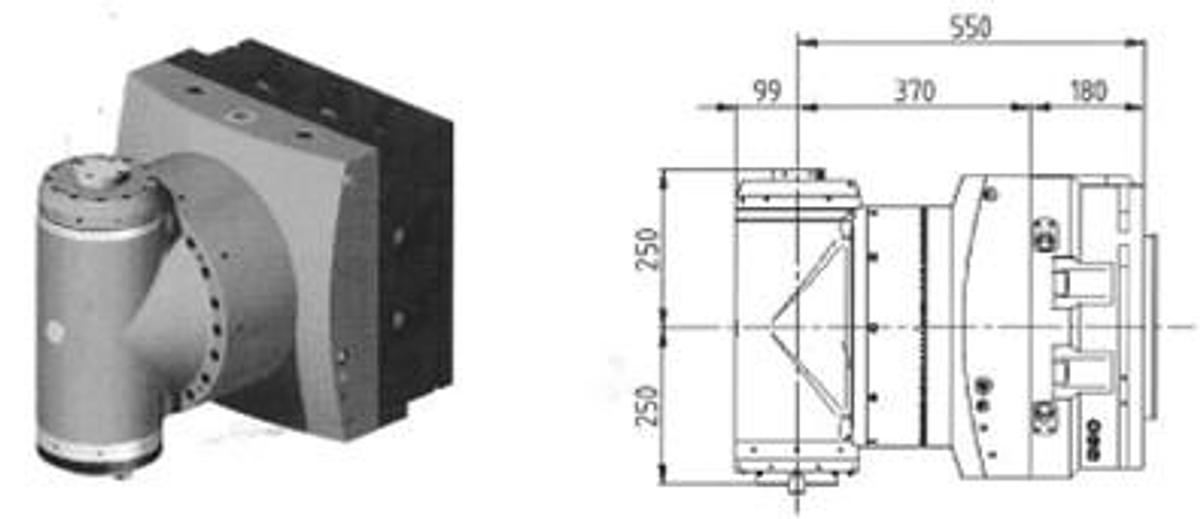

Angular Milling Head IFVW 101 C-E

- Automatic tool clamping.

- Indexed head rotation of 1°

- External and internal tool cooling

- Automatic loading and clamping on the machine

- Clamping cavity on the spindle (DIN 69871 – AD) ISO 50

- Max. power (from 240 rpm) 25kW

- Max. torque (up to 240 rpm) 1,000 Nm

- Max. rotation 1,600 rpm

- Transmission ratio between machine spindle and headstock spindle 1:1

- Head rotation 0-360 degrees

- Weight 500 kg

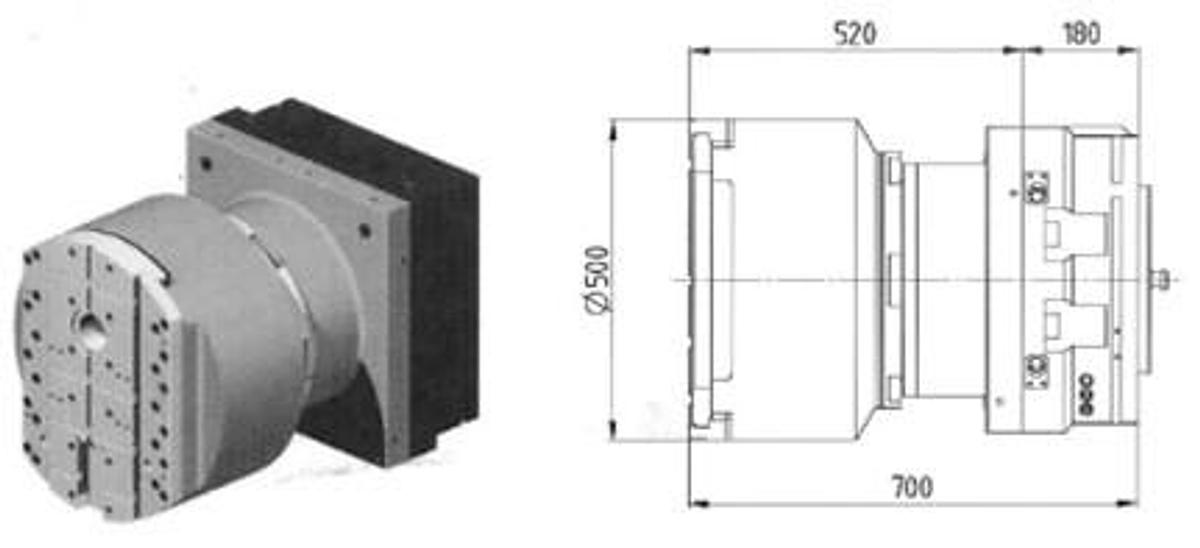

Facemill Head IWD

- The rotational movement is derived from the machine spindle's rotation.

- The expansion movement is derived from the machine spindle's advancement.

- Automatic loading and fixation in the machine.

- Max. torque 6,300 Nm

- Max. rotation 100 rpm

- Maximum force in boring 20,000 N

- Maximum force in facing 14,000 N

- Transmission ratio between the machine drive shaft and the facing 1:1

- Facing stroke 90 mm

- Facing feed 0.75 – 1,000 mm/min

- Maximum facing diameter 1,465 mm

- Weight 580 kg

Specifications

| Manufacturer | Skoda |

| Model | HCW 1-150 5/14M |

| Year | 2015 |

| Condition | Used |

| Stock Number | 5654299 |

| Spindle diameter | 150 mm |

| Center diameter of milling spindle | 235 mm |

| Spindle speeds | 3,000 rpm |

| X axis travel | 14,000 mm |

| Y axis travel | 5,000 mm |

| Z axis travel | 1,200 mm |

| W axis travel | 1,000 mm |

| Z + w - ram + spindle travel | 2,200 mm |

| Table dimensions | 4,000 x 4,000 mm |

| Table capacity | 70 Ton |

| V axis table travel | 2,500 mm |

| B axis rotational | 360° |

| B axis indexing | 0.0001° |

| Ram dimensions | 400 x 400 mm |

| Main motor power | 71 kW |

| Max torque | 7000 Nm |

| Spindle taper | ISO 50 |

| Feed rates X/Y | 0.5 - 20,000 mm/min |

| Feed rates Z/W | 0.5 - 15,000 mm/min |

| Feed force X/Y/Z | 35,000 N |

| Feed force W | 30,000 N |

| Bed guideway width | 1,650 mm |