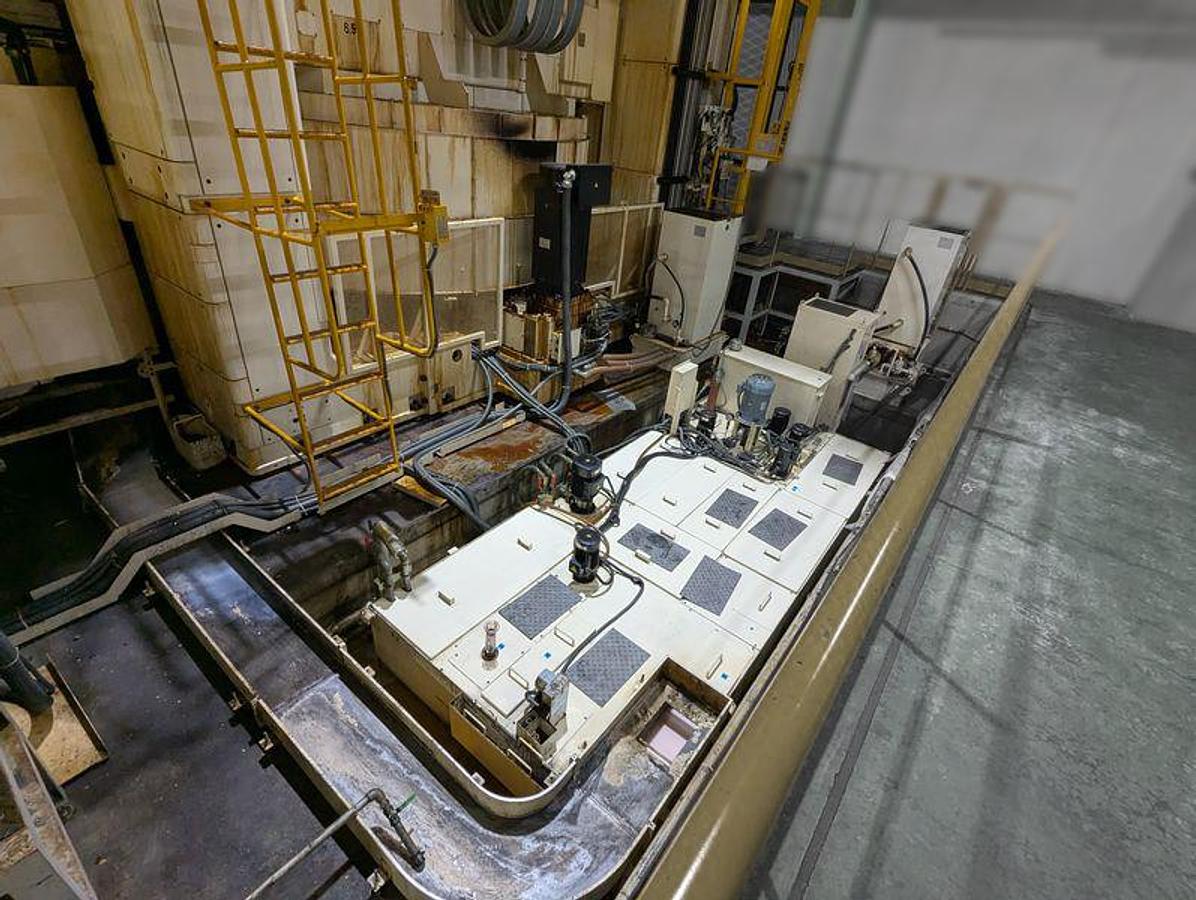

Okuma TN 350 CNC Vertical Turning Boring & Milling Machine with Live Spindle & Table C-Axis

Okuma TN 350 CNC Vertical Turning Boring & Milling Machine with Live Spindle & Table C-Axis

or

Call 770-509-0744

Description

OSP-P200L CNC Control

Vertical spindle attachment - 30 - 4,000 rpm

(S4000/L250/22kW/non-indexable/through-spindle compatible)

90° angular attachment - 30 - 3,000 rpm

(S3000/L150/22kW/indexing every 180°/oil hole block attached)

Tool shank type: MAS BT50

Maximum number of tools: 12 turning holders, 22 milling tools, 1 cover

Eight-jaw single-acting table 3,200 mm Diameter

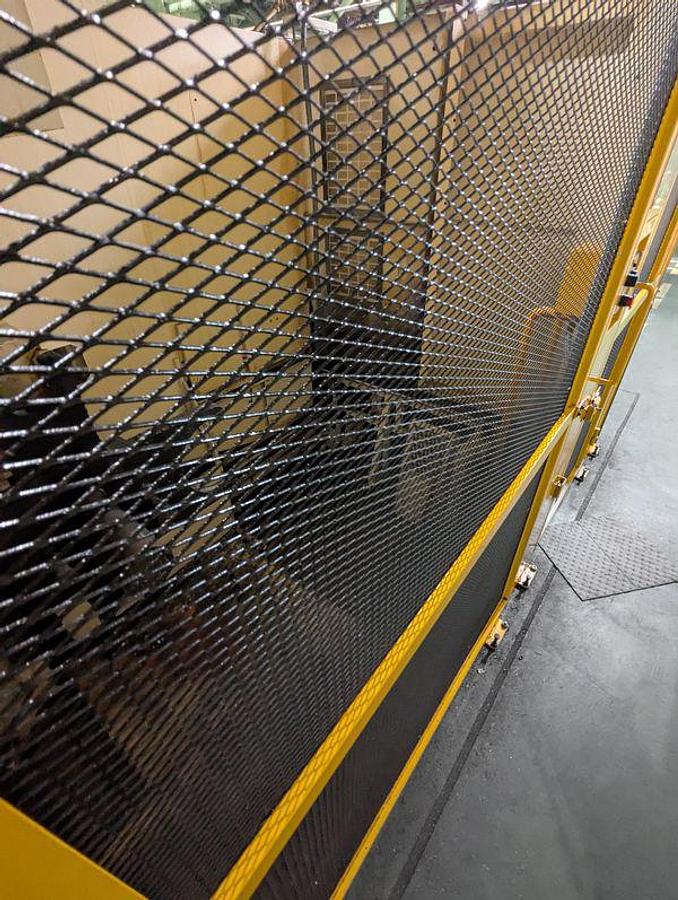

Kawata Tech 8-jaw X-axis telescopic cover

2,000L cutting fluid tank (rear-mounted)

High-pressure coolant system (2 MPa)

Chip conveyor

Automatic cutting edge measurement and correction device

X/Z-axis absolute scale

Automatic measurement and automatic origin correction function

Renishaw RMP60

Crossrail Lift 790mm

Crossrail positioning: 125mm x 7 points, 4 control axes

Specifications

| Manufacturer | Okuma |

| Model | TN 350 |

| Year | 2010 |

| Condition | Used |

| Stock Number | 5654270 |

| Table diameter | 3,200 mm |

| Swing | 3,500 mm |

| Turning height | 1,400 mm |

| Table capacity | 20,000 kg |

| Table turn speed | 1 - 49 rpm |

| Live spindle speed | 4,000 / 3,000 rpm |

| X axis travel | 4,000 mm |

| Z axis travel | 800 mm |

| Crossrail lift | 790 mm |

| Spindle taper | MAS BT50 |

| C axis | 0.001° |

| Max turning torque torque (30 min/cont.) | 42,800 / 35,000 Nm |

| Machine dimensions | 10,330 x 8,000 x 5,865 mm |

| Machine weight | 47,000 kg |