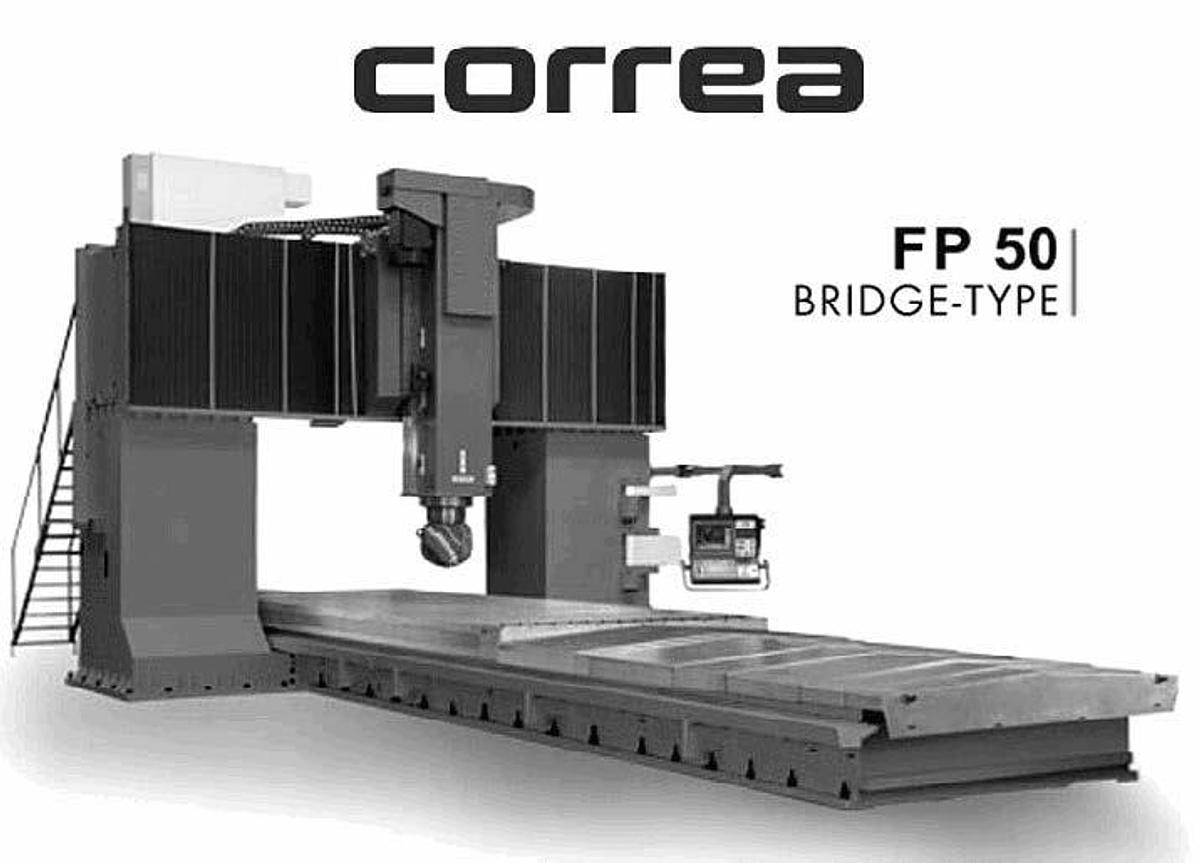

Correa FP 50/50 CNC Bridge Type Machining Center

Correa FP 50/50 CNC Bridge Type Machining Center

Description

Rebuilt & Retrofitted in 2025

Heideinhain iTNC 640 CNC Control

Milling Head:

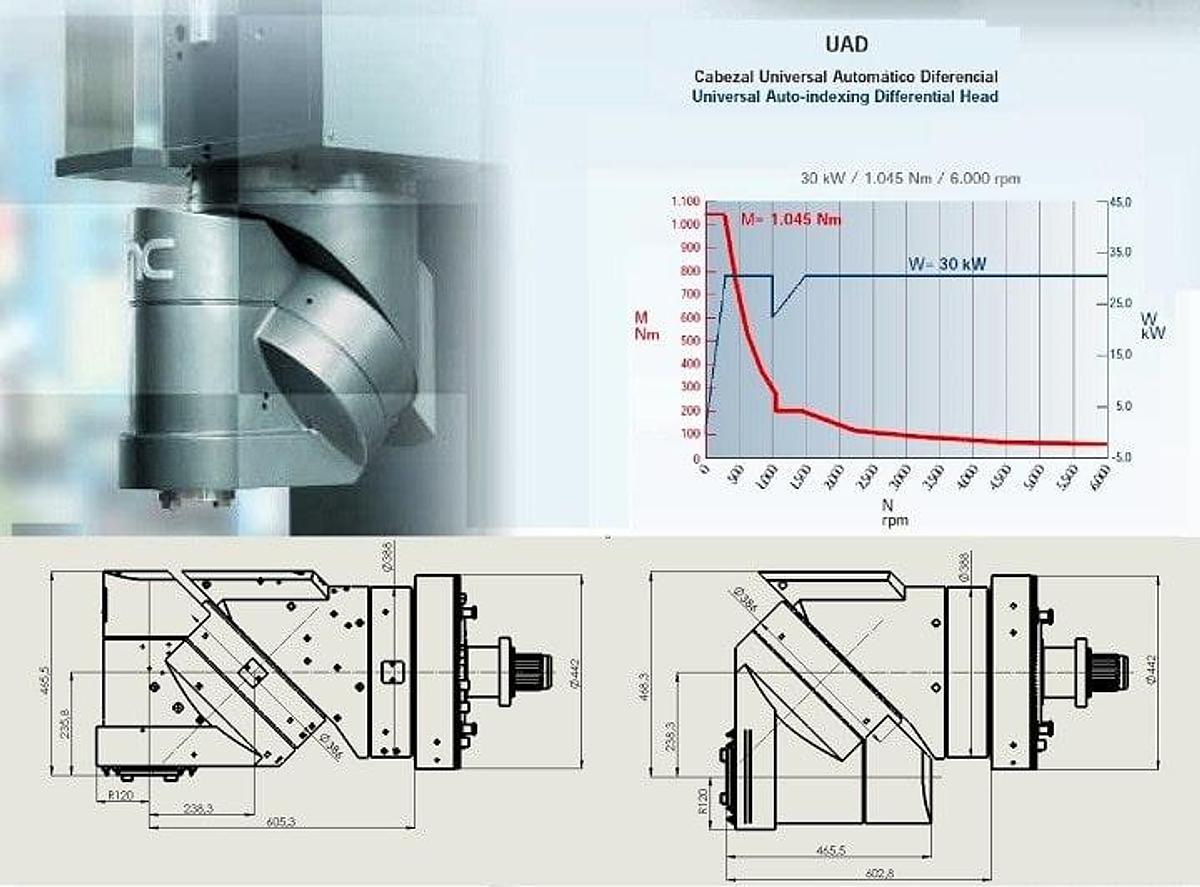

Head Type Automatic Auto-index. differential/UAD(0,1º)

Tool clamping system - Hydraulic

Taper nose - ISO 50 (DIN69871) / Tirante-Pull stud: DIN69872

Speed range - 6,000 rpm

Spindle power - 30 kW

Machine Guarding

External & High Pressure Through Spindle Coolant

Chip Conveyor

NEW HR-250 Electronic Handwheel

Retrofit Completed with the Following Updates:

GENERAL:

Disassembly of structural elements.

General inspection of the machine structural elements in its X, Y, Z axes.

Cleaning, sanding and painting of structural elements.

AXES

X AXIS:

Inspection of table guideways.

Ballscrews preloading adjustment.

Bearings replacement.

Inspection and cleans of lubrication circuits.

Inspection of telescopic protections and replace new wipers.

Grinding or sanding of the working table.

Y-Z AXES:

Replacement and adjustment of biplast and/or plates.

Ballscrews preloading adjustment.

Axis drive inspection (bearings, pulleys, belts…).

Inspection and cleans of lubrication circuits.

Inspection of telescopic protections.

HEAD - RAM:

Inspection of spindle drive chain inside the ram with a replacement of the damage elements.

Complete dismantling the head for an inspection.

Replacement of damage bearings and gears.

Main axis rounds out calibration.

ELECTRICAL:

Installation of new CNC HEIDENHAIN TNC-i640.

Installation of new electrical cabinet plate and new drivers.

Inspection of X-Y-Z and spindle motors.

New control panel installation.

AUXILIARY ELEMENTS AND ACCESORIES:

Inspection of hydraulic, refrigeration, lubrication… circuits of machine and head.

Vertical counterbalance system inspection.

Revision and replacement of damage parts on accessories, ATC, rotary tables… (only when the machine is equipped with these

accessories).

MACHINE ADJUSTMENTS:

Geometry setup and functionality of machine axis, performing the acceptance test protocols of geometry.

SAFETY:

Repair or replace all the damage elements of the guarding.

New perimetral fence installation.

MACHINE TESTING START-UP AT NC SERVICE:

Machine PLC installation or upgrading.

A full functionality testing.

Axis adjustments.

Accessories starting up.

Alarms testing.

Specifications

| Manufacturer | Correa |

| Model | FP 50/50 |

| Year | 2004 |

| Condition | Used |

| Stock Number | 5654220 |

| Between columns | 2,700 mm |

| Spindle speeds | 6,000 rpm |

| X axis travel | 5,000 mm |

| Y axis travel | 3,250 mm |

| Z axis travel | 1,000 mm (V/C 450 / 1,450 mm) |

| Table size | 5,600 x 2,000 mm |

| Table capacity | 25,000 kg |

| Spindle drive motor | 30 kW |

| Spindle taper | ISO 50 DIN 69871 |

| Rapid traverse x axis | 7,200 mm/min |

| Rapid traverse y, z axis | 12,000 mm/min |

| Machine dimensions | 13,200 x 5,425 x 5,350 mm |

| Machine weight | 56,000 kg |