NEW Schiess Vertimaster VM 3.5 CNC Vertical Turning Boring & Milling Machining Center

NEW Schiess Vertimaster VM 3.5 CNC Vertical Turning Boring & Milling Machining Center

Description

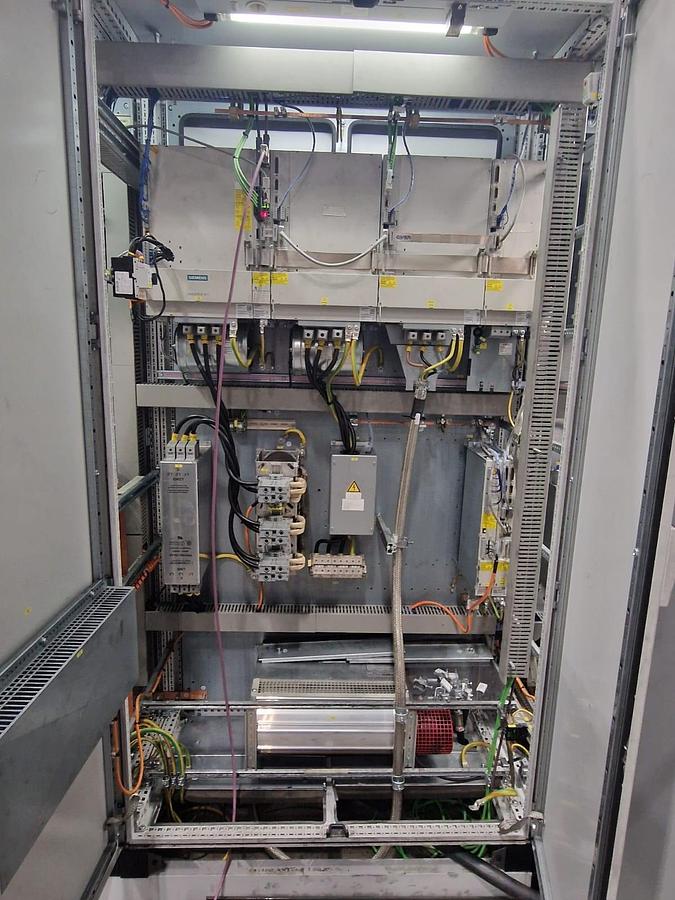

Siemens SINUMERIK 840D CNC Control

60 Position Automatic Tool Changer

6 Position Automatic Head Changer

Straight Drilling & Milling Head GB 1 B

3,150 rpm - 52 kW - 2,400 Nm - SK50 - Internal/External Coolant Supply

Angle Drilling & Milling Head WB 1 PB

3,150 rpm - 30 kW - 1,400 Nm - SK50 - Internal/External Coolant Supply

Universal Drilling & Milling Head UB 05 B

4,000 rpm - 30 kW - 400 Nm - SK 50 - ±95° A-Axis Swiveling Range - Internal/External Coolant Supply

Multiple Turning Tool Holders

2x3 Capto C8 Horizontal - 55 kN Cutting Force - Internal/External Coolant Supply

Turning Tool Holder PA PM

2.5° Position Steps - 200 kN Automaatic Clamping Force - Internal/External Coolant Supply

Chip Conveyor

Coolant Equipment (1,200 L Tank)

External Coolant Supply

40 l/min - 4 bar

Internal Coolant Supply

15 - 25 l/min - 30 bar

Machine Accuracy

1) Positioning accuracies

according to DIN VDI 3441

• Positioning uncertainty X-axis / Z-axis 0.01/1,000 mm

• Positioning uncertainty W-axis 0.015/1,000 mm

• Positional deviation X-axis / Z-axis 0.005/1,000 mm

• Positional deviation W-axis 0.007/1,000 mm

• Positioning uncertainty of face plate C1-axis 10 arcsec

• Positional deviation of face plate C1-axis 5 arcsec

2) Geometric Accuracies

Acc. To DIN 8609 part 3

• Flatness of clamping surface

0.01 up to 1000mm Ø

Plus 0.01 for each 1000mm Ø

• Axial run of clamping surface

0.01 mm up to 1000 mm Ø

Plus 0.01 mm for each 1000 mm Ø

• Radial run of faceplate

0.01 mm up to 1000 mm Ø

Plus 0.005 mm for each 1000 mm Ø

• Rectangularity of crossrail movement in respect to faceplate

a) in longitudinal direction 0.02/1,000 mm

b) in cross direction 0.02/1,000 mm

• Parallelism of cross movement of slide to faceplate

0.02/1,000 mm

• Rectangularity of ram movement to faceplate

a) in longitudinal direction 0.03/1,000 mm

b) in cross direction 0.03/1,000 mm

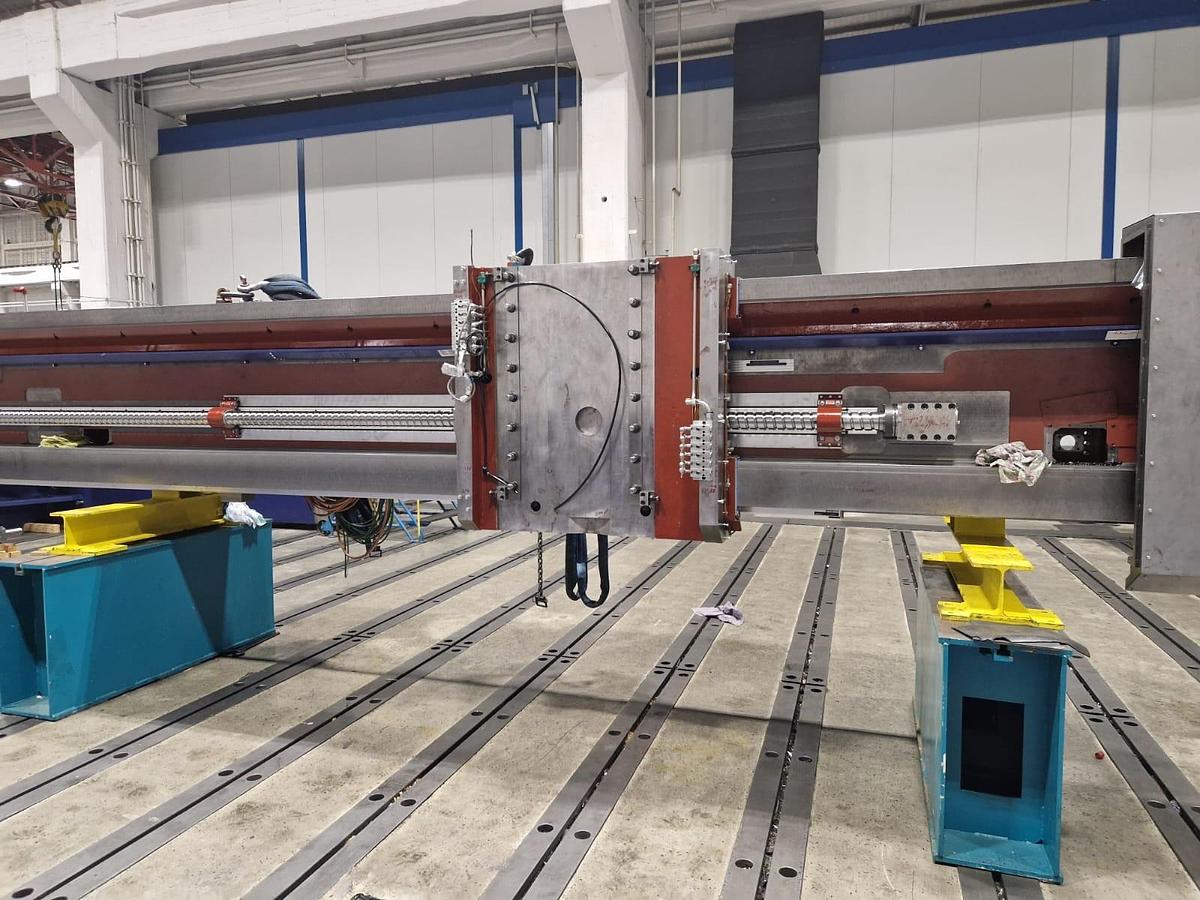

Working area

Max. machining diameter 4,000 mm

Max. workpiece height 2,800 mm

(Distance between face plate surface and GB 1B head)

Face plate

Diameter 3,500 mm

Number of clamping jaws 4 pcs.

Max. clamping force each 120 kN

Width of T-slots 36 H12

Center hole 110 H7

Drive power (2 x 40 kW) 80 kW/AC

Speed stepless for turning operation 0 – 136 rpm

Speed stepless for milling operation 0 – 6 rpm

Max. torque 50 kNm

Max. load 50 Ton

Saddle (X-axis)

Travel from faceplate center to left 3,800 mm

Travel from faceplate center to right 2,000 mm

Max. positioning speed 0 – 16,000 mm/min

Max. feed force 30 kN

Cross rail (W-axis)

Travel stepless 1,200 mm

Max. positioning speed 4,000 mm/min

Ram (Z-axis)

Cross section 280x240 mm

Travel 1,600 mm

Min. bore to enter 390 mm

Feed / rapid traverse rate 0 – 16,000 mm/min

Max. cutting force to turning operation

Boring and milling head (Masterhead-Principle)

(ref. to standard head GB 1B)

Drive power S1 (100% ED) 52 kW

Number of gears 2

Spindle speed

Range 1 0-180-520 rpm

Range 2 0-1,100-3,150 rpm

Spindle torque

Range 1 2,400-2,400-850 Nm

Range 2 450-450-160 Nm 75 kN

Specifications

| Manufacturer | Schiess |

| Model | Vertimaster VM 3.5 |

| Year | 2025 |

| Condition | Used |

| Stock Number | 5654214 |

| Table diameter | 3,500 mm |

| Swing | 4,000 mm |

| Turning height | 2,800 mm |

| Table capacity | 50 Ton |

| Table turn speed | 136 rpm |

| Live spindle speed | 3,150 rpm (2 ranges) |

| Z axis travel | 1,600 mm |

| W axis travel | 1,200 mm |

| Live spindle motor | 52 kW |

| Spindle taper | SK 50 |

| Ram size | 280 x 240 mm |

| Electrics | 380V - 50 Hz - 24 V - 250 kVA |