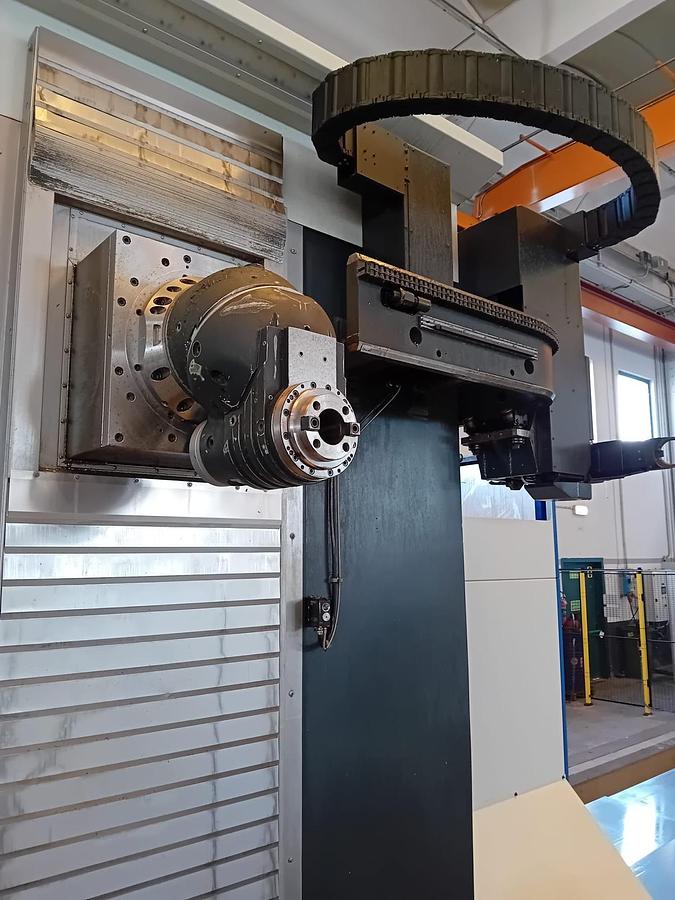

FLP 8000 CNC Floor Type Horizontal Boring Machine

FLP 8000 CNC Floor Type Horizontal Boring Machine

Description

Heidenhain TNC 640 CNC Control

Control console equipped with HEIDENHAIN digital numerical control mod. TNC 640 (19" TFT video) and a keyboard designed for total machine control. Version with a processor for controlling 10 axes plus the spindle. Main panel equipped with individual

buttons for the linear axes (X+, X-, Y+, Y-, Z+, Z-). Standard milling, drilling, and boring cycles and corresponding tests are included.

60 Position Chain Type Automatic Tool Changer

Functions for rotating the rotary-translational unit, tilting tables, and table functions. 3D machining for mold machining and process times of 0.5 ms.

• V13. HEIDENHAIN remote electronic handwheel, model hR-510, 5 m cable.

• The entire machine structure is made entirely of CAST IRON (base, carriages, upright and slide), extensively ribbed and dimensioned.

• Electronic compensation of the expansion of the carriage-slide assembly in all three dimensions.

• X, Y, and Z axes equipped with INA linear guide system, size SSDL (oversized version), consisting of rollers with 4 perpendicular recirculation channels, with cylindrical rollers on a precision hardened and ground carriage, with 4 orthogonal guides.

• X axis equipped with 8 roller shoes in SSDL size (oversized version).

• Y and Z axes equipped with 8 slides per axis; 6 roller slides of size SSDL (oversized version)+ r 2 damping slides.

• Linear recirculating roller guides (INA) ensure high dynamics and rigidity, as well as high positioning accuracy and axis repeatability. The sliding system prevents wear caused by friction in conventional sliding systems.

• X-axis guide on fixed table protected by a telescopic metal guard

• Upper and lower parts of the upright protected at the front by a metal roller shutter and total lateral closure of the vertical movement.

• X-axis with rack and pinion movement, double pinion, double reducer, and double motor.

• Y and Z axes with hardened and ground recirculating ball screws (G25 quality) with preloaded nut.

• Automatic lubrication of the slide guides and ball screws.

• Hydraulic balancing system for the vertical Y axis.

• High torque HEIDENHAIN 37143 kW (S1IS6) in-line spindle motor. Liquid thermostat with electrical cooling unit.

• NC17. Independent servo drives for each axis with HEIDENHAIN digital AC motors.

• HEIDENHAIN pressurized optical lines on X, Y, and Z axes (accuracy +/-0.0005 mm) with a compressed air system to protect against dust on all axes.

• Work area lighting

• Electrical cabinet. The electrical cabinet complies with European standards EN-60204. The electrical cabinet contains the following main devices:

- transformer for power supply and auxiliaries

speed regulator for the head motor and for the AC servomotors of the axes

Thermal and magnetothermal protection devices for the auxiliary and power circuits of the machine. Main switches interlocked with the doors when in the ON position, lockable with padlocks.

Power supply: three-phase 400 V +1-10%, 50 Hz Relative

humidity (average annual value): max 75%

• Hydraulic equipment integrated into the machine, built to DIN 24346 (ISO 4413) standards and including:

30-liter tank on standard machine

Motor pump for transporting oil to the machine at 3 liters/min and 150 bar on the standard machine Solenoid valves for controlling the various mechanisms of the machine Pressure switch for automatic pressure control in the circuit

- A visual oil level indicator and an electronic one

Identification labels affixed to hydraulic and pneumatic components, pipes, and fittings

Centralized hydraulic, pneumatic, and lubrication unit for easy maintenance

Specifications

| Manufacturer | Soraluce |

| Model | FLP 8000 |

| Year | 2021 |

| Condition | Used |

| Stock Number | 5654212 |

| Spindle speeds | 4,000 rpm |

| X axis travel | 8,000 mm |

| Y axis travel | 2,200 mm |

| Z axis travel | 1,500 mm |

| Table dimensions | 2,000 x 2,000 mm |

| Table capacity | 20 Ton |

| W axis travel table travel | 1,500 mm |

| Spindle motor power | 37 / 43 kW |

| Spindle torque | 900 / 1,045 Nm |

| Taper of boring spindle | ISO 50 |

| Rapid feeds x, y, z, axis | 35 m/min |

| Total power requirement | 400V - 50 Hz - 59 kVA |

| Machine dimensions | 13,790 x 3,182 x 4,280 mm |

| Machine weight | 36,500 kg |