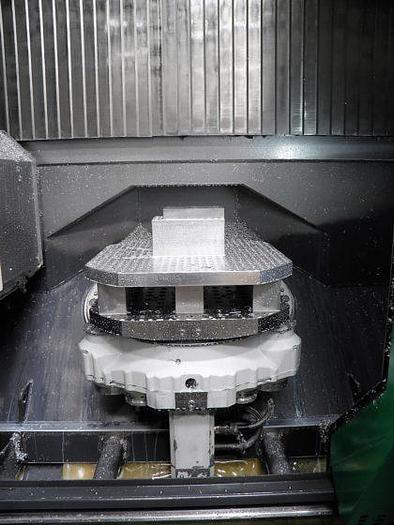

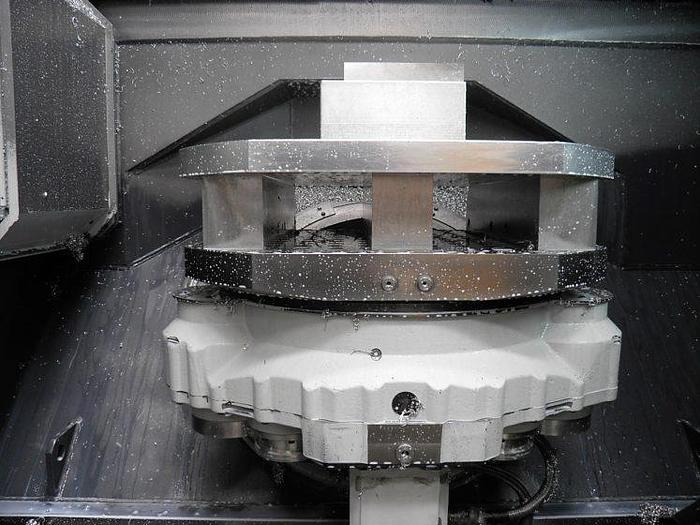

Unisign Unipro 5-P CNC High Speed Pendulum Vertical Machining Center with 2 Separate Work Zones

Unisign Unipro 5-P CNC High Speed Pendulum Vertical Machining Center with 2 Separate Work Zones

Description

Siemens Sinumerik 840D CNC Control – Numerically Controlled in 4 or more Axes – Optional Up to 30 Axes 2 Work Zones Automatic Tool Change – 63 Pocket Magazine Tool Loading Bay at the Machine Front Face for Tool Loading During Machining Closed Loop Cooling System with Chilling Unit for Main Drive and the Electrical Cabinet for Increased Thermal Stability Clamping Table Mounting Face at 45 Degree Inclination for Optimal Chip Removal and Easiest Integration of Various Configuration of Clamping Tables Integrated Chip Conveyor Coolant Supply Through the Spindle & Tool Coolant System – 320 L& Pump 40 L/min – 4 bar Full Enclosure Guarding Section with Front Sliding Doors and Electronic Safety Door Locks – Integrated Separator for 2 Completely Separated Work Zones Compressed Air Required 20 L/min – 6 bar Fume Extraction via 2 Electrostatic Filter Units

Specifications

| Manufacturer | Unisign |

| Model | Unipro 5P |

| Year | 2006 |

| Condition | Used |

| Stock Number | 10497 |

| Spindle speed | 12,000 rpm |

| X axis travel | 2x 1,000 mm |

| Y axis travel | 800 mm |

| Z axis travel | 500 mm |

| Table dimensions | 680 x 680 mm |

| Swing circle | 800 mm |

| Thrust in x,y axis | 10,000 N |

| Thrust in z axis | 13,000 N |

| Rapid traverse of the x,y,z axes | 60 m/min |

| Feed rate | 5 - 60,000 mm/min |

| Electrical equipment for power system | 400 V / 3 ph / 50 Hz |

| Power consumption, approximate | 70 KVA or 100 KVA |

| Maximum work piece height | 450 mm |

| Maximum speed of rotation | 32 rpm |

| Admissible transport load | 750 kg |

| Maximum torque of rotation | 3,000 Nm |

| Measuring of position | Direct via Rotary Encoder |

| Machine dimensions | 8,600 x 3,500 mm |

| Machine height | 3,700 mm |